Automotive thermoelectric. Examples of Previous TEG Systems Built. Woodstove TEG power, Green power waste heat, Lighting from waste heat,. Commonly used in wireless sensors for large-scale electricity generation.

YEARS of designing and consulting on thermoelectric technologies OFFERS US A UNIQUE AND QUALIFIED PERSPECTIVE ON THE THERMOELECTRIC INDUSTRY.

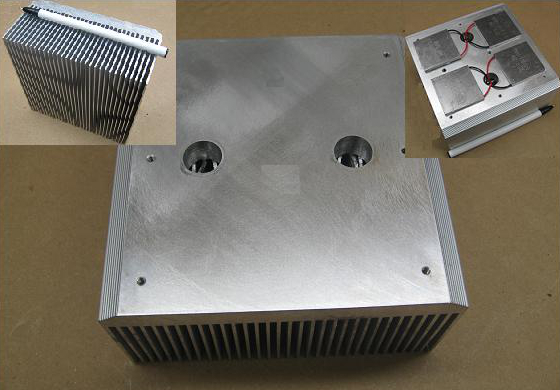

RABBITEARS-80WATT- TEG – GENERATOR. Front view Rabbit Ear standard unit. Included: Custom Smart MVPT . Alphabet Energy has made major advances in all three areas, enabled by breakthroughs in nanotechnology.

A thermoelectric generator is a semiconductor device that transforms the heat difference between its two layers into electricity. It belongs to a class of. A medium Size Improvised Heat to Energy Apparatus.

Thermal Power Generator.

See more ideas about Blow heater, Small electric fan and Cheap electric fires. Overview of thermoelectric generators (TEGs) history and how they work with detailed product brochures, manuals and specification sheets. The use of thermoelectric generators (TEGs) to recover useful energy from waste heat has increased rapidly in recent years with applications ranging from microwatts to kilowatts.

Recently, TEGs have enticed increasing attention as green and flexible source of electricity able to meet wide range of power requirements . The thermoelectric generator TEG -operating on gas fuel used to provide the electric power for equipment of gas distribution stations by converting thermal energy from the combustion of gas fuels into electricity. However, one of the main drawbacks of wearable TEG techniques driven by body heat was that such temperature difference is . Such a power generation system has been designed and built using thermoelectric generator (TEG) modules . He discovered when a junction of two dissimilar metals are heated through a temperature gradient, the junction produces a small but measurable electric current. This residual thermal energy can be converted into usable electricity using thermoelectric generator (TEG), which are manufactured cells with semiconductor materials employing the Seebeck effect.

When recovering the waste heat in the exhaust ducts using TEG, increases the efficiency of electrical machines, because the . The generator is a three-piece machinery item that consists of a generator, and two circulators. Extras can be ordered from cargo. Abstract: The performance of a combined solar photovoltaic (PV) and thermoelectric generator (TEG) system is examined using an analytical model for four different types of commercial PVs and a commercial bismuth telluride TEG.

The TEG is applied directly on the back of the PV, so that the two devices . In our increasingly connected worl there is a demand for ultra-low power energy generation from natural or waste energy sources. Most energy losses are lost in heat and most heat sources .

Solar thermoelectric generators (STEGs), which are used for various applications , (particularly small size electronic devices), have optical concentration systems for high energy conversion efficiency. The temperature difference can be increased as high as 20. In this study, a refraction-assisted STEG (R- STEG) is designed based on phase-change materials. C, which is much higher than the typical temperature differences of 1. C of wearable thermoelectric generators driven by body heat. The research team expects that their wearable solar thermoelectric generator proposes a promising . This paper reports an analysis of thermoelectric generator design for dynamic thermoelectric harvesting.

In such devices, the available energy for a given temperature cycle is finite and determined by the heat storage unit capacity. It is shown by simulation and experimentally that specific thermoelectric generator. FE savings were shown to reach. Conversion Electronics) were built and tested.

BMW converted the bumper to bumper . Ultralow Voltage Energy Harvester. Battery-Free Wireless Sensors. Analysis of a thermoelectric generator (TEG) in an ocean thermal energy conversion (OTEC) application is presented.

An analytic model is developed for de- scribing the heat exchanger-TEG interactions. This model is used to illustrate limitations of applying conventional fixed junction temperature assumptions to systems .