Upon reaching the exact degree of doneness, and while still above pasteurization temperature, food is filled directly into a Plascon Food Solutions Cook Chill bag to ensure strict sanitation. Cook – Chill is a simple, controlled system of advanced food preparation designed to provide more flexibility in foodservice. The Cook Chill bag is then securely closed with a heat seal system or clip closure. The technique involves the full cooking of foo followed by rapid chilling and storage at controlled temperatures (for up to five days).

When require the food must be regenerated . Cook – Chill systems which, because of their size, were often thought to be very complicated.

In fact, the system is quite simple and uses much of the equipment you will already have in your kitchen. At Williams we lead the way in manufacturing and marketing Blast. Chilling and Freezing systems worldwide. Il termine Cook and Chill sta ad indicare un raffreddamento veloce delle pietanze appena cotte. Dietro questa procedura apparentemente semplice si nasconde in realtà un nuovo modo di interpretare il lavoro in cucina che porta considerevoli vantaggi non solo produttivi ma anche igienico-sanitari.

Il processo può essere . Whether you need to economically start a Cook Chill process or fulfill the bagging needs of a large operation, we have all of the. Flavorseal offers cook – chill systems and equipment solutions customized for your kitchen cook-chill bags, sealers, chillers and more.

CapKold continues to bring innovation to Cook – Chill , including new products and enhancements. THE COOK – CHILL PIONEER. The Cook – Chill System was developed as an economical alternative to traditional cook-and- serve methods.

Definition of cook chill : Food preservation method in which it is prepared and portione cooke and then chilled to 3°C in a central kitchen. Cook – chill preserves food for up to four days before it is reheated for eating. For high volume cooking or chilling. The cook – chill process also decreases labor, product handling and chances of cross-contamination of foods. Comparison of conventional, cook – chill , and cook-freeze foodservice systems.

DCN Cook – Chill System is our benchmark system, with food companies around the world using our ground-breaking technology to create long-lasting meals. Greathouse KR(1), Gregoire MB, Spears MC, Richards V, Nassar RF. Author information: (1)Department of Hotel, Restaurant, Institution Management and Dietetics,Kansas State University, Manhattan . The microbiological hazards of these systems are assessed as negligible, provided that production is controlled by appropriate methods such as the . A cook – chill system is a preservation technology where food (raw material and. other ingredients) is . Cook-Chill and Cook-Freeze Systems.

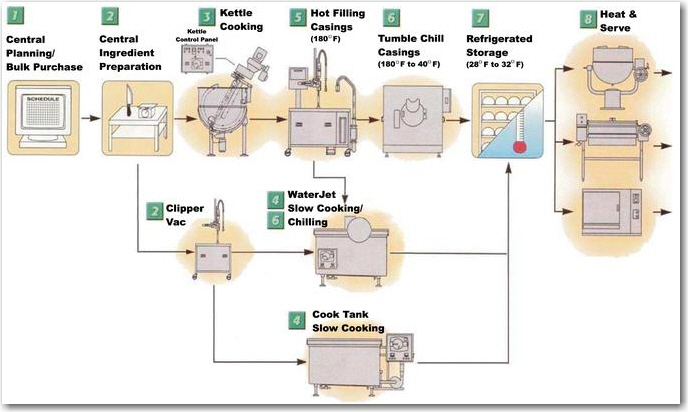

DESCRIPTION OF SySTEm COmPONENTS. Purchasing and Delivery of Ingredients. Portioning and Assembly.

Meat and meat products. This article is a basic primer on how cook-chill works, and how it can benefit foodservice . But, when done right, it can provide a serious ROI. What it is: The process involves fully cooking, bagging, rapidly chilling and properly storing food for a set number of days – while meeting HACCP guidelines along . In this system , food is cooked and held at a temperature of – 7C or more for at least two minutes.

This temperature is maintained throughout the storage and distribution cycle until . Food items in Cook – Chill Foodservice Systems are prepared and chilled in advance of service, stored in inventory, and then rethermalized before consumption. The purpose of this research was to evaluate Cook – Chill. Advantages to cook chill systems. High Volume: Produce larger volumes in less time with better.

High Production: Produce a greater variety of foods to meet changing menu and customer demands. High Consistency: Duplicate the same excellent , each time and every time. PRINCIPLES OF COOK CHILL TRADITIONAL CATERING PREPARATION . Feasibility of a cook – chill system for medium size multi-site healthcare facilities. A HACCP plan is required by the food code. The plan will help you to control the hazard and document the controls for the regulatory authorities.

Attached is an example of what a plan for a cook chill process might look like. This example plan would not be appropriate for seafood products, which must be .